| Sign In | Join Free | My uabig.com |

|

| Sign In | Join Free | My uabig.com |

|

| Categories | Tinplate |

|---|---|

| Model Number: | MR SPCC DR8 Q195L S08AL SPTE |

| Certification: | ISO |

| Place of Origin: | JIANGSU |

| MOQ: | 1 MT |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 2000MT/Month |

| Delivery Time: | 3~15 days |

| Packaging Details: | Exporting package/wooden box package/Or per customers’ requirement |

| Name: | T4 T5 Coated Gold Lacquered 0.15mm 0.5mm Prime Electrolytic Tinplate Coils Sheets |

| Internal Lacquer: | White/ Gold/ Aluminium |

| Hardness: | T1-T5 |

| Temper: | T1-DR9 |

| Application: | Food Cans |

| Tin coating:: | 2.8/2.8, 5.6/5.6, 2.8/5.6 |

| Company Info. |

| JIANGSU LIANZHONG METAL PRODUCTS (GROUP) CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

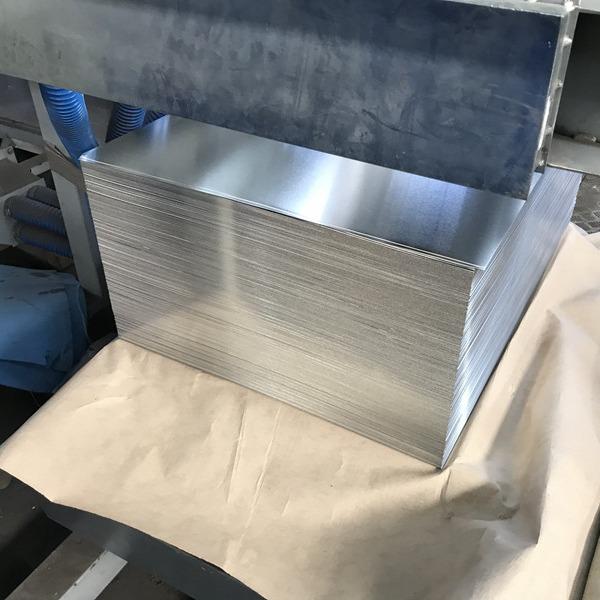

| Tin-plated steel plate (commonly known as tinplate) is a steel

product with a stampable thin steel plate as the base, tin plating

on the surface, and multiple protective films (layers). It has the

characteristics of corrosion resistance, non-toxic, odorless,

glossy surface, light weight, high strength (compared to paper,

wood, composite materials), easy to print, easy to weld and

process, and has strong adaptability to ambient temperature.

Therefore, more than 70% of the total output of tin-plated steel

sheets is used for packaging of food and beverages. In addition, it

is also a packaging and raw material supplier for industries such

as chemical and pharmaceutical, mechanical and electrical,

hardware, telecommunications and instrumentation. |

|

Features:

Product | Printed tinplate sheet | Thickness | 0.14-0.55mm | |

Base Metal | Tinplate or TFS sheet | Width | 600-1050mm | |

Internal Lacquer | White/ Gold/ Aluminium | Annealing | BA or CA | |

External Printing | Printing/ Clear | Temper | T1-T5, DR7-DR9 | |

Internal Strip Coating | White powder | Coating | 1.1-15.1g/m2 | |

Application | Food and industry cans | Print | CMYK off-set printing | |

Color | CMYK/ PMS | Origin | China | |

Delivery Time | 20-30 days | MOQ | 25MT | |

Coating weight

Item | Former Coating | Coating Weight | Nominal Coating Weight | Minimum average |

Designation | Code | (g/m2) | (g/m2) | |

Equally Coated | 10# | 1.1/ 1.1 | 1.1/ 1.1 | 0.9/ 0.9 |

20# | 2.2/ 2.2 | 2.2/ 2.2 | 1.8/ 1.8 | |

25# | 2.8/ 2.8 | 2.8/ 2.8 | 2.5/ 2.5 | |

50# | 5.6/ 5.6 | 5.6/ 5.6 | 5.2/ 5.2 | |

75# | 8.4/ 8.4 | 8.4/ 8.4 | 7.8/ 7.8 | |

100# | 11.2/ 11.2 | 11.2/ 11.2 | 10.1/ 10.1 | |

Differentially Coated | 25#/ 10# | 2.8/ 1.1 | 2.8/ 1.1 | 2.5/ 0.9 |

50#/ 10# | 5.6/ 1.1 | 5.6/ 1.1 | 5.2/ 0.9 | |

50#/ 25# | 5.6/ 2.8 | 5.6/ 2.8 | 5.2/ 2.5 | |

75#/ 25# | 8.4/ 2.8 | 8.4/ 2.8 | 7.8/ 2.5 | |

75#/ 50# | 8.4/ 5.6 | 8.4/ 5.6 | 7.8/ 5.2 | |

100#/ 25# | 11.2/ 2.8 | 11.2/ 2.8 | 10.1/ 2.5 | |

100#/ 50# | 11.2/ 5.6 | 11.2/ 5.6 | 10.1/ 5.2 | |

100#/ 75# | 11.2/ 8.4 | 11.2/ 8.4 | 10.1/ 7.8 | |

125#/ 50# | 15.1/ 5.6 | 15.1/ 5.6 | 13.9/ 5.2 |

Applications:

Tin plating is widely used for electroplating applications in a

range of industries including electronics, aerospace, jewellery

manufacture, but perhaps the most common application for tin

plating solution is the tin cans that are widely used for storing

food products. The tin plating process is also utilised in the

making of pots, pans, and other cookware known as tinware, as well

as in the manufacture of electronic parts and components.

Advantage:

|